Utility-Scale

Pitch Control Systems

Custom designed to meet individual wind turbine requirements

using verified Windurance components

Servo Pitch Electric Blade Control Systems

Windurance offers a range of blade pitch actuator controls serving the needs of utility-scale wind turbines. Compliance with IEC 61400-1 Wind Turbine Design Requirements for safety and protection is demonstrated in all Windurance pitch control platforms. Industry-leading embedded condition monitoring, including life experience historians for the whole pitch actuator drive train, has made Windurance pitch actuator solutions the one to emulate worldwide.

Founded on the belief that the industry would not be well served through the application of reconfigured industrial control or drive products, Windurance has created pitch actuators fit for the wind industry service with a total focus on the pitch actuator application. Working with wind turbine designers and aeroelastic engineers, Windurance’s post-processing model of aeroelastic time series for the IEC Design Load Cases (DLCs) assures that all aspects and dimensions of the pitch actuator performance envelope are accurately determined, applied to the engineering details of hardware and software platforms, implemented and verified to that requirement.

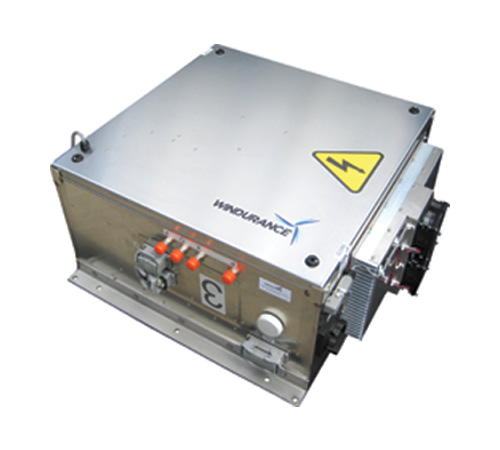

Servo Pitch Control System

This is the ORIGINAL! Windurance Servo Pitch is the wind industry’s first commercial servo electric pitch control system and it set the stage for advanced controls in widespread use throughout the world today. With first production scale deployments beginning in 2003, Windurance Servo Pitch regulated turbines remain in safe, reliable operation in Europe, the United States, Mexico, and China to this day. Available models are suitable for turbines up to 3 MW.

-

Individual Blade Pitch Control supports advanced turbine control methods

-

Patented low to zero volt ride-through with very low cost

-

Robust AC mains tolerant to grid voltage transients and line swells

-

Transient voltage, electrostatic discharge (ESD), and lightning protection

-

Exceeds EMC Immunity standards called for by IEC 61400-1

-

Standard Industrial Bus Interfaces

-

Low-cost, long-life SLA Battery or zero maintenance Ultracapacitors power back up solutions

Servo Pitch Control System LRU

Servo Pitch LRU is the original Servo Pitch reconfigured to simplify manufacturing and maintenance operations. It consists of highly modular control components that can be installed or replaced with minimum tools and effort. This Line-Replaceable Unit (LRU) implementation, typical throughout the rail transport and aerospace industries, offers a far more efficient manufacturing process, field service, and maintenance while greatly reducing spare parts inventory costs on sites. Available models are suitable for turbines up to 3 MW.

-

Package Certified High Temperature; 50 degrees C, High Humidity 100%RH

-

Individual Blade Pitch Control supports advanced turbine control methods

-

Patented low to zero volt ride-through with very low cost

-

Robust AC mains tolerant to grid voltage transients and line swells

-

Transient voltage, electrostatic discharge (ESD), and lightning protection

-

Exceeds EMC Immunity standards called for by IEC 61400-1

-

Standard Industrial Bus Interfaces

-

Low-cost, long-life SLA Battery or zero maintenance Ultracapacitors power back up solutions

i-Pitch System

Permanent Magnet Brushless motors offer tremendous advantages over DC brush machines, ranging from much higher acceleration with lower torque to zero maintenance operation; with no brushes. However, in the wind turbine blade pitch actuator application, safety plays a critical role, and brushless motor servo controls are fraught with prospective common mode failure mechanisms.

That’s why Windurance developed iPitch using our patented safety design for brushless pitch actuators. Continuing in the modular LRU package design approach, widely lauded by Operations and Maintenance managers and turbine technicians, iPitch offers high-performance individual blade pitch controls for turbines up through 10MW or higher.

-

Robust design for wind turbine conditions and environment

-

Extensive built-in condition-based monitoring

-

Fault tolerance to extreme AC mains supply transients, differential short circuit, and ground fault short circuits on all input and output power and control signals, as well as IEC 62305 Protection Against Lightning

-

Integral patented grid HVRT, LVRT, and ZVRT features

-

Ultracapacitor power back up

-

Fast and easy assembly and servicing requires few tools and little time

-

On-board, sophisticated diagnostic software, helps diagnose turbine operational conditions

-

Permanent Magnet Brushless Servo Motors and Closed Loop Servo Controls provide higher speed and torque

-

Smooth EFC Velocity Profile for reduced turbine stress

-

-40 to +50 C operating temperature

-

Up to 20 years of design service life, with virtually no maintenance requirements